HOT PRODUCTS

Leeming est une entreprise de haute technologie intégrant la R&D, la production et la distribution, et fournit un concasseur, une fabrication de sable, des équipements de broyage, une station de concassage mobile

cement mill grinding procedure

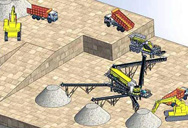

Les concasseurs à mâchoires ne fonctionnent généralement pas indépendamment, mais avec les concasseurs à cône, les concasseurs à percussion, les machines de fabrication de sable, les tamis vibrants, etc., constituent un ensemble complet de systèmes de traitement du sable et du gravier pour obtenir un traitement précis du minerai et de la roche et améliorer la pertinence du produit, Augmenter sa valeur marchande.Les lignes de production courantes sont: la ligne de production de pierre et la ligne de production de sable.

Ligne de production de pierre

Sur la base de la ligne de production de pierre, un équipement de machine de fabrication de sable pour le concassage fin et le façonnage est ajouté, ce qui permet de réaliser la production simultanée de sable et de pierre concassée fabriqués à la machine. peut répondre aux diverses exigences de traitement des clients., Pour atteindre l'objectif "d'une ligne à usages multiples", c'est un choix de ligne de production idéal pour produire des matériaux de surface d'autoroute, des agrégats de sable et de gravier de chemin de fer à grande vitesse, du sable et du gravier de la centrale hydroélectrique matériaux, terminaux portuaires et pistes aéroportuaires.

Energy and cement quality optimization of a cement

2018年7月1日 This study aimed at optimizing both the energy efficiency and the quality of the end product by modifying the existing flowsheet of the cement grinding circuit. As a

Click

Click

Grinding process optimization - IEEE Xplore

2017年6月19日 Grinding process optimization — Featuring case studies and operating results of the modular vertical roller mill. Abstract: As a world-wide leader in grinding

Click

Click

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

The process variables in cement grinding process using VRM are strongly nonlinear and having large time delay characteristics also dynamics changes within 2-4 minutes. The

Click

Click

OPTIMIZING THE CONTROL SYSTEM OF CEMENT MILLING:

Abstract - Based on a dynamical model of the grinding process in closed circuit mills, efficient efforts have been made to optimize PID controllers of cement milling. The

Click

Click

Cement grinding optimisation - ScienceDirect

2004年11月1日 To optimise cement grinding, standard Bond grinding calculations can be used as well as modelling and simulation techniques based on population balance

Click

Click

Modeling of energy consumption factors for an industrial cement ...

2022年5月9日 Lin, X. Liang, J. Modeling based on the extreme learning machine for raw cement mill grinding process. in Proceedings of the 2015 Chinese Intelligent

Click

Click

Overview of cement grinding: fundamentals, additives,

2017年5月19日 Grinding is an essential operation in cement production given that it permits to obtain fine powder which reacts quickly with water, sets in few hours and hardens over a period of weeks....

Click

Click

Process control for cement grinding in Vertical Roller Mill (VRM) a

2017年10月1日 Abstract The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the

Click

Click

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process.In recent years, the VRM cement mill has been equipped in

Click

Click

Manufacture of Portland Cement - Process and

2020年4月13日 All the cement plants set up after 1980 use the dry process for the manufactures of cement. But the method of preparing the wet process and flow diagram of mixing of raw materials are given

Click

Click

11.6 Portland Cement Manufacturing - U.S. Environmental

L. Clinker grinding -17 M. Cement silos -18 N. Cement load out -19 O. Raw mill feed belt -24 P. Raw mill weigh hopper -25 Q. Raw mill air seperator -26 R. Finish grinding mill feed belt -27 S. Finish grinding mill weight hopper -28 T. Finish grinding mill air seperator -29 U. Preheater kiln 3-05-006-22

Click

Click

Process control for cement grinding in Vertical Roller Mill (VRM)

2017年10月1日 Abstract. The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding ...

Click

Click

Chapter Six: Some Operating Guidelines - Vertical Roller Mill

2022年4月6日 Many ask me about the procedures for starting and operating the vertical roller mill, a grinding machine used in the cement industry. I have to confess that answering that question is complicated.

Click

Click

Design of clinker grinding system; mill and separator

In cement and other mineral processing plants, grinding process requires a considerab le amount of power. Grinding of the clinker consumes about 1/3 of the power required to produce 1 ton of cem ent.

Click

Click

Cement Production Process Cement Manufacturing Process AGICO CEMENT

2020年8月25日 A full cement production process includes the cement crushing process, raw mill process, clinker process, and cement grinding process, cement packing process, and related process. Find more! Skip to content +86 13683722138. info@cement-plants. about. blog. contact. EN ES. about. blog.

Click

Click

Cement Manufacturing Process Phases Flow Chart Cement

2012年8月30日 Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand clay fulfill the need of silicon, iron and

Click

Click

Energy and exergy analyses for a cement ball mill of a

2020年2月1日 Request PDF Energy and exergy analyses for a cement ball mill of a new generation cement plant and optimizing grinding process: A case study Nowadays, ball mills are used widely in cement ...

Click

Click

Clinker grinding technology in cement manufacturing

2019年1月3日 Clinker grinding technology is the most energy-intensive process in cement manufacturing. Traditionally, it was treated as "low on technology" and "high on energy" as grinding circuits use more than 60 per cent of total energy consumed and account for most of the manufacturing cost. Since the increasing energy cost started

Click

Click

Grinding process optimization - IEEE Xplore

2017年6月19日 As a world-wide leader in grinding solutions for the cement industry and understanding the changing needs of cement producers and how to tailor solutions to meet those needs. Optimizing output, improving efficiency, and reducing CO2 emissions while keeping investment costs to a minimum are common challenges that the modular vertical

Click

Click

Ventilation Prediction for an Industrial Cement Raw Ball Mill by

2021年6月10日 1. Introduction. In the cement industry, grinding is one of the most consuming energy stages in the production units. Around 65% of the total used electrical energy in a cement plant has to be utilized to grind raw materials, coal, and clinker [1,2].Through the process, many variables can affect the efficiency and productivity of

Click

Click

Modeling of energy consumption factors for an industrial cement ...

2022年5月9日 Lin, X. Liang, J. Modeling based on the extreme learning machine for raw cement mill grinding process. in Proceedings of the 2015 Chinese Intelligent Automation Conference 129–138 (2015).

Click

Click

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL

The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 30-40% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and having

Click

Click

Cement Grinding Unit Cement Grinding Plant Cement Grinding

Cement grinding unit cost. Take the annual output of 600,000 tons of large-scale cement grinding station as an example, there are three common options can be recommended: SCHEME 1: roller press + φ 3.2 ×13m ball mill; SCHEME 2: φ 3.8 ×13m closed mill; SCHEME 3: clinker fine crusher + cement roller press+φ 3.2 ×13m ball mill.

Click

Click

The impacts of dry stirred milling application on quality and ...

2020年8月15日 Throughout the studies, the data related to cement grinding process was collected from two different cement grinding circuits of Bursa Cement Plant/Turkey. Turkish cement sector with 90 million tons of capacity is in the first place of European production, and third and fourth in export and production in the world rankings

Click

Click

Cement Grinding - Cement manufacturing process - Priya Cement

Clinker is extracted from our clinker tank and transported to the cement mill hopper by belt conveyors. A measured quantity of clinker and gypsum is fed into our closed-circuit ball mill which incorporates with a high-efficiency separator. OPC is produced by the inter-grinding and blending of 95% clinker with 5% gypsum to a fineness of 280 m 2 /kg.

Click

Click

How Is Cement Produced in Cement Plants Cement Making Process

Generally, the proportion of components in cement raw materials is 67-75% limestone, 10-15% clay, 0.5-1.5% iron ore and 8.5-11% coal. The laboratory of a cement plant. With the help of vertical roller mills or other types of crushers, the raw materials are blended and further ground into smaller pieces of raw meal in the cement plant.

Click

Click

Prediction of cement specific surface area in the cement mill grinding ...

2022年4月25日 The accurate prediction of the cement specific surface area aims to guide operators to control the cement grinding process to improve product quality while reducing system energy consumption. However, due to the complexity of the cement grinding process, the process variables have coupling, time-varying delay, nonlinear

Click

Click

Modeling and Optimization of Cement Raw Materials Blending Process

Strictly speaking, the blending process does not include the cement ball mill grinding process. Before cement raw materials are transported into the cement burning kiln, cement raw material blending process is considered as a whole process, thus the grinding process could be seen as part of blending process. For integrity and

Click

Click<< Previous : Concasseur De Fabrication De Poussière Allemand