HOT PRODUCTS

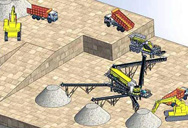

Leeming est une entreprise de haute technologie intégrant la R&D, la production et la distribution, et fournit un concasseur, une fabrication de sable, des équipements de broyage, une station de concassage mobile

operation and principle of vibrating screen pdf

Les concasseurs à mâchoires ne fonctionnent généralement pas indépendamment, mais avec les concasseurs à cône, les concasseurs à percussion, les machines de fabrication de sable, les tamis vibrants, etc., constituent un ensemble complet de systèmes de traitement du sable et du gravier pour obtenir un traitement précis du minerai et de la roche et améliorer la pertinence du produit, Augmenter sa valeur marchande.Les lignes de production courantes sont: la ligne de production de pierre et la ligne de production de sable.

Ligne de production de pierre

Sur la base de la ligne de production de pierre, un équipement de machine de fabrication de sable pour le concassage fin et le façonnage est ajouté, ce qui permet de réaliser la production simultanée de sable et de pierre concassée fabriqués à la machine. peut répondre aux diverses exigences de traitement des clients., Pour atteindre l'objectif "d'une ligne à usages multiples", c'est un choix de ligne de production idéal pour produire des matériaux de surface d'autoroute, des agrégats de sable et de gravier de chemin de fer à grande vitesse, du sable et du gravier de la centrale hydroélectrique matériaux, terminaux portuaires et pistes aéroportuaires.

Construction Working and Maintenance of Vibrators and Vibrating

common types of screens depending upon the principle of operation. Fixed/Static Screens Fixed screens are static steep inclined (35-50°) structures to assist material flow with

Click

Click

Principles of Screening and Sizing - 911 Metallurgist

Principles of Screening and Sizing Presented By: George Schlemmer Today’s Agenda Provide you with information to promote a safer, more cost efficient operation. Topics

Click

Click

A review on the advanced design techniques and methods of

2019年4月1日 The screening performance and mechanical reliability of a vibrating screen depends on the kinetic properties according to the law of coal-screening principle, the

Click

Click

Dynamic design theory and application of large

2009年9月1日 Show abstract. PDF The reliability is a key factor for the design and manufacture of large vibrating screen. In the paper, we

Click

Click

A review on the advanced design techniques and methods of

2019年4月1日 The dynamic response stability of the vibrating screen is an important factor affecting the screening effect and the structural performance of the vibrating

Click

Click

Horizontal Screens Schenck Process make Vibrating Screens

principle. The vibrating screens perform a linear movement at an angle of impact to the horizontal, generating the movement of the material. Overcritical systems are applied.

Click

Click

TECHNICAL NOTES 4 VIBRATING SCREENS

The basic method of operation of a screen is very simple. The screen presents a barrier to the passage of oversize material while it readily passes undersize material. It is only

Click

Click

Vibrating Screens: Design, Process and Operation Request PDF

2023年3月1日 Vibrating Screens: Design, Process and Operation March 2023 Publisher: Sharif University of Technology Authors: Saghar Farajzadeh University of Tehran

Click

Click

Vibration screening: A detailed study using image ... - ScienceDirect

2020年8月1日 Screening is an old and simple separation operation, from boxes with manual operation up to those operating at industrial flow rates, where there is a

Click

Click

TECHNICAL NOTES 4 VIBRATING SCREENS

4.1 Classification Based on Sieving - Vibrating screens The basic method of operation of a screen is very simple. The screen presents a barrier to the passage of oversize material while it readily passes undersize material. It is only necessary to ensure that each particle has an opportunity to reach the screen.

Click

Click

Screening Theory and Practice - Triple/S Dynamics

B. The Shaking Screen: 475 rpm, 1” stroke, zero pitch, 6 deg. slope. C. The Inclined Vibrating Screen: 1200 rpm, 1/4” vertical circle dia. D. The Horizontal Vibrating Screen: 840 rpm , 1/2” stroke at 45°. Each has a .063” dia. wire screen with 1/8” clear opening, moving under a particle travelling

Click

Click

Types Of Vibrating Screen and How It Works - JXSC Machine

2021年7月27日 Our vibrating screen can make single, double, three and four layers and the screening effect of 2-layer screen is the best. Our screen has higher screening efficiency and productivity because of the strong vibration of the screen box reduce the material blocking the screen holes. Meanwhile our vibrating screen is with simply

Click

Click

Installation and Operation Manual - FRIEDRICH Schwingtechnik

Vibration motors are provided and are suitable for driving vibrating systems, such as e.g.: vibrating conveyor chutes, vibrating pipes, screen conveyors, screening machines, spiral conveyors, automatic sorting machines, knock-out grates, vibrating trestles, resonance conveyors, vibrating mills and fluid-bed dryers, bin vibrating machines, etc.

Click

Click

Variable elliptical vibrating screen: Particles kinematics and ...

2021年11月1日 CDU operation panel was connected to the laptop using a gigabit network. Images taken by the high-speed camera were saved and replayed. To perform quantitative analysis of velocity trends for particles during the screening of EAS and VEVS, 50–9 and 9–6 mm coal fractions were dyed with spray paint to mark tracer particles to help overall

Click

Click

Banana screen working principle and Operation rules LZZG

2. It is forbidden to start the sieve machine until the various protective covers are not fixed; 3. Do not stand within one meter of the screen machine during the start and stop of the screen machine; 4. When the sieve machine is in operation, do not stand on the vibrating parts; 5. The screen motor must be de-energized and the screen machine ...

Click

Click

How does the vibrating screen work? Haiside

2021年6月7日 The vibrating screen works by using the double-rotation vibration generated by the vibrator. The upper rotating weight of the vibrator makes the screen surface vibrate in plane, while the lower rotating weight makes the screen surface vibrate the cone surface. Its combined effect The effect is that the screen surface produces

Click

Click

VIBROSCREEN® - Kason - PDF Catalogs Technical

Broadest Range Solves Specialized Problems % OPEN AREA Kason VIBROSCREEN® circular vibratory screeners handle bulk chemicals, minerals, plastics, foods, dairy products, pharmaceuticals and other materials ranging from dry bulk solids to solids-laden slurries. They range in diameter from 18 to 100 in. (460 to 2540 mm) and are offered with ...

Click

Click

operation of vibrating screens pdf Mining Quarry Plant

2013年8月28日 Vibrating screen and feeder machine, operation, working principle extec screeners workshop manual finding cg of vibrating screen pdf complete trex trf ic vibrating screen user manual – BINQ Mining

Click

Click

Horizontal Screens Schenck Process make Vibrating Screens

principle. The vibrating screens perform a linear movement at an angle of impact to the horizontal, generating the movement of the material. Overcritical systems are applied. This enables the vibrating screen to be operated stably and makes it extremely insensitive to unsteady loads. Classifying of bulk materials such as: • Sinter • Pellets ...

Click

Click

YZS Series Circular Vibrating Screen - Shanky Machinery

YK series circular vibrating screen mainly consists of the eccentric block vibrator, screen box, motor, and supportive device. Its vibrating track is a circle and moves on a circular motion. It is a multi-layer and high efficient vibrating screen. Motor drives the V-belt to make the eccentric block rotate in high speed, so that producing large ...

Click

Click

Linear Vibratory Feeders and their Working Principles - Gough

Working Principles. Like all vibrating feeders, an electromagnetic vibrating feeder moves product by making the feeder tray vibrate. The product sits in the tray. When the tray vibrates, the product moves in a series of small hops. This series of hops combine to create the constant motion of the product. The direction of movement is determined ...

Click

Click

HEAVY DUTY INCLINED VIBRATING SCREENS - Deister Machine

2) Feed Tonnage Method S = F x C (S = Screen cloth area F = TPH feed) The above areas are approximate for feeds containing up to 60% of oversize and having 50% of the undersize smaller than one-half the screen opening. C= Square Feet of Screen Surface for each TPH of feed. 3) Depth of Bed Method T x K. D.

Click

Click

[PDF] Crack Detection Method of Vibrating Screen Beam Based

2017年4月1日 Vibrating screen is one of the important washing equipment in coal washery, and it is mainly used to grading, dielectric recovery, raw coal cleaning, etc. The safe operation of vibrating relates to the coal mine production safety directly. After continuously run for a long time, various faults of vibrating screen cannot be avoided,

Click

Click

Modeling and parameter optimization for the design of vibrating

2015年11月9日 Compared with traditional linear vibrating screens, the force, stratification mechanisms, and throwing principles of the material on the screen’s surface were studied, and the vibrating screens ...

Click

Click

Introduction to Rotary Vibrating Screen - LinkedIn

2015年9月9日 Introduction and working principle: Rotary vibrating screen is designed as a high-precision screening machinery. Round vibrating sieve is composed of vertical motor,and eccentric weight ...

Click

Click

A review on the advanced design techniques and methods of vibrating ...

2019年4月1日 In reality, a large vibrating screen, which has a screen surface width of no less than 3.6 m and a screening area of no less than 20.0m 2, usually oscillates with extremely complex dynamic characteristics of the screen body [10, 11].As shown in Fig. 2 (b), generally, except for the dominated strong alternating load yielded by two box-type

Click

Click

A review on the advanced design techniques and methods of vibrating ...

2019年4月1日 A brief description of the importance and content of advanced design techniques and methods for vibrating screen will be presented in Section 2 and then a detailed state-of-the-art review from three aspects will be given in 3 Kinetic properties of screen body by dynamic modeling, 4 Screening operational parameters by DEM, 5

Click

Click

The role of sand linear vibrating screen

2022年4月27日 Machine-made sand linear vibrating screen is a heavy-duty screening equipment (Model 1836) produced by us. The overall model is solid and durable, made of high-quality Q235 carbon steel, with a ...

Click

Click

6 Important Things I Learnt About Pharmaceutical Vibro Sifter

A vibro sifter is made of electrical and mechanical parts. That is, the motor converts electrical energy into mechanical energy (vibratory motion). Machine conforms to the cGMP requirements; this includes the choice of material and hygiene. It is for this reason the machines are made from high quality stainless steel.

Click

Click<< Previous : Division De Flottation De Colonne De Flottaison

>> Next : Roche De Marbre Blanc